ATEX risk: the security of working with people who can manage assessment, designing, installation and maintenance in areas with explosion risks

Managing the explosion risk effectively requires multidisciplinary skills in chemistry, process safety and protection systems, as well as electrical and mechanical skills.

It involves different functions and business processes and impacts significantly on worker safety, but also on your company’s business risk.

With its staff, 3p Safety can intervene with professionalism and competence for both targeted consultancy and complex ATEX projects on Italian and international industrial companies and groups.

Atex Audit and feasibility studies

- Contractual requirement analysis according to areas and substances used

- Analysis of directives and standards applicable to machines and lines

- Safety meeting with suppliers and customers to define and analyse supply and contractual specifications

- Technical verification of conformity of the machine or of specific functional groups with drafting an intervention report

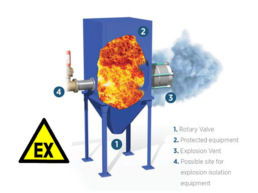

Classification of explosion risk zones

- Analysis of production processes and the physical-chemical characteristics of substances

- Classification of explosion risk zone due to the presence of flammable fluids or gases according to EN 60079-10-1 and the presence of combustible dusts and fibres according to EN 60079-10-2.

- Identification of technical measures for the reduction or downgrading of zones

ATEX risk analysis and Explosion protection document

- Ignition sources analysis according to EN 1127-1

- Analysis of risk scenarios, ignition probability and expected damage

- Atex risk assessment and definition of a detailed improvement and adjustment plan

Training for workers, maintainers and engineering

- Practical training for workers exposed to the explosion risk based on the results of the explosion risk assessment

- Training of maintenance and engineering staff on the management of purchase, commissioning and maintenance for equipment in the Ex area

- Training on the job

Purchase and contract consulting for machines and plants in ATEX areas

• Analysis of the contractual requirements of machines and plants subject to the ATEX directive

• Analysis of the directives and standards applicable to machines and lines

• Safety meeting with suppliers and customers to define and analyse supply and contractual specifications

• Technical verification of conformity of the machine or of specific functional groups with drafting an intervention report

Mapping and verifying compliance of ATEX equipment in action

- Verification in the plant of electrical and mechanical equipment and protection systems installed in ATEX zones

- Verification of the physical marking of components and the relative documentation (certificates and instructions for use)

- Drafting the compliance report and identification of adjustment operations on machinery and plants